Optical-Requirements-on-External-Optical-Surface

Customer Documentation

Customer Documentation: Neonode® Touch Sensor Module User's Guide : Optical Requirements on External Optical Surface

Created by

Unknown User (petter.dahlman), last modified on May 15, 2017

The optical properties on cover glasses placed in front of the sensor are essential in order to maintain a high touch performance – if light is lost, scattered or diverted it will lead to shorter detection range and lower touch accuracy.

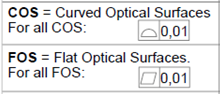

Optical Requirements

- Transparency: > 90% at 975nm

- Tool surface finish: SP1-A2 (max Ra 0.05µm).

- Flatness: ±0.05 mm per 10 mm

- Shape accuracy: ±0.05 mm

- In the plastic injection tools. avoid placing gates and ejector pins on optical surfaces.

- Haze is not allowed on optical surfaces or within the light path.

Geometrical Constraints

The zForce AirModule is an optical system that both emits and receives reflected IR-light at different indecent angles. When light hits a transparent material most of the light transmitted through the material and exits on the other side. In reality the amount of light being transmitted is angle dependent why some shape constraints exist on windows placed in front of the sensor.

- Parallel window surfaces

- Maximum angle:

Mirror Surface

- Planparallella, tolerans?

-

- Minst TBD % transparens @975nm

- Surface finish: SPI-A2 (?)

Attachments:

Document generated by Confluence on Sep 11, 2025 11:02